3D Matter Made to Order

Cluster of Excellence of Karlsruhe Institute of Technology (KIT) & Heidelberg University

3D Additive Manufacturing Driven Towards the Molecular Scale

The Cluster of Excellence is a collaboration of Karlsruhe Institute of Technology (KIT) and Heidelberg University (Uni HD). It pursues an interdisciplinary approach through conjunction of natural, engineering, and life sciences. 3DMM2O establishes scalable digital 3D Additive Manufacturing transcending from the molecular to the macroscopic scale.

This approach converts digital information into functional materials, devices and systems “made to order.” 3DMM2O creates a powerful technology push and pull by treating molecular materials, technologies and applications as indissolubly intertwined.

On the technology side, the scientific challenges are “finer, faster, and more”, i.e., advance technologies for printing from molecular materials in terms of resolution and speed by orders of magnitude, while vastly expanding the possibilities for multi-material printing.

On the application side, we aim at functional 3D hybrid optical and electronic systems, 3D artificial materials called metamaterials, and at reconstructing functioning organotypic systems by using 3D scaffolds for cell culture.

Prof. Dr. Martin Wegener

Karlsruhe Institute of Technology

martin.wegener@kit.edu

Prof. Dr. Christine Selhuber-Unkel

Heidelberg University

selhuber@uni-heidelberg.de

News

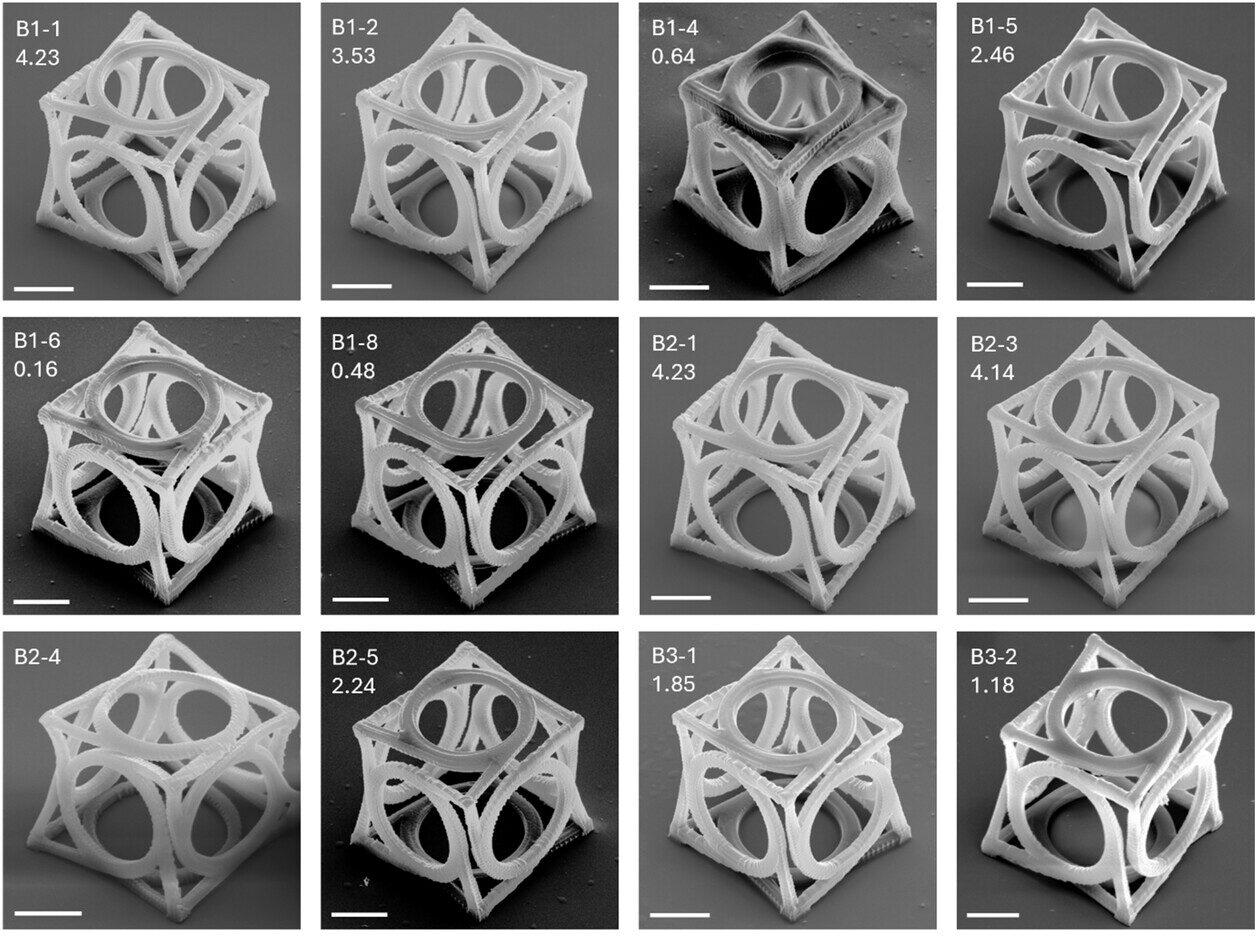

Photoinitiator Design for Two-Step 3D Laser Nanoprinting

In this study, including Cluster Postdoctoral Researcher Aleksandra Vranic, Doctoral Researcher Jonathan L. G. Schneider, Principal Investigators Martin Wegener and Stefan Bräse, and Cluster Alumnus Pascal Rietz, a systematic investigation of new photoinitiators for two-step absorption–based 3D laser nanoprinting is presented. The authors synthesized 23 benzil-based (1,2-diketone) molecules and evaluated their solubility, printability, and required laser power; fourteen enabled stable 3D microstructures using a single 405 nm continuous-wave laser. Two-step absorption relies on real excited states instead of simultaneous two-photon excitation, enabling polymerization at lower laser power with simpler setups. Systematic molecular variation revealed clear structure–performance correlations, supporting more energy-efficient and accessible micro- and nanofabrication strategies.

© Vranic et al., ChemPhotoChem (2026), CC BY 4.0.

New Explain Like I’m Five video: Could Light Be the Future of Computing?

As computers become more powerful, their energy demands increase, motivating research into technologies that could enable faster, more energy-efficient information processing. In the latest episode of our “Explain Like I’m Five” video series, we feature Cluster Doctoral Researcher Erik Jung, who works under the supervision of Principal Investigator Wolfram Pernice at the Universität Heidelberg. In the video, Jung explains his research on photonic chip technologies, which process information using light instead of electrical signals. These technologies rely on extremely small, high-precision structures fabricated using advanced 3D printing and integrated directly onto semiconductor chips. The Explain Like I’m Five series invites doctoral researchers to present their research topics in an accessible format that makes complex scientific ideas understandable beyond disciplinary boundaries.

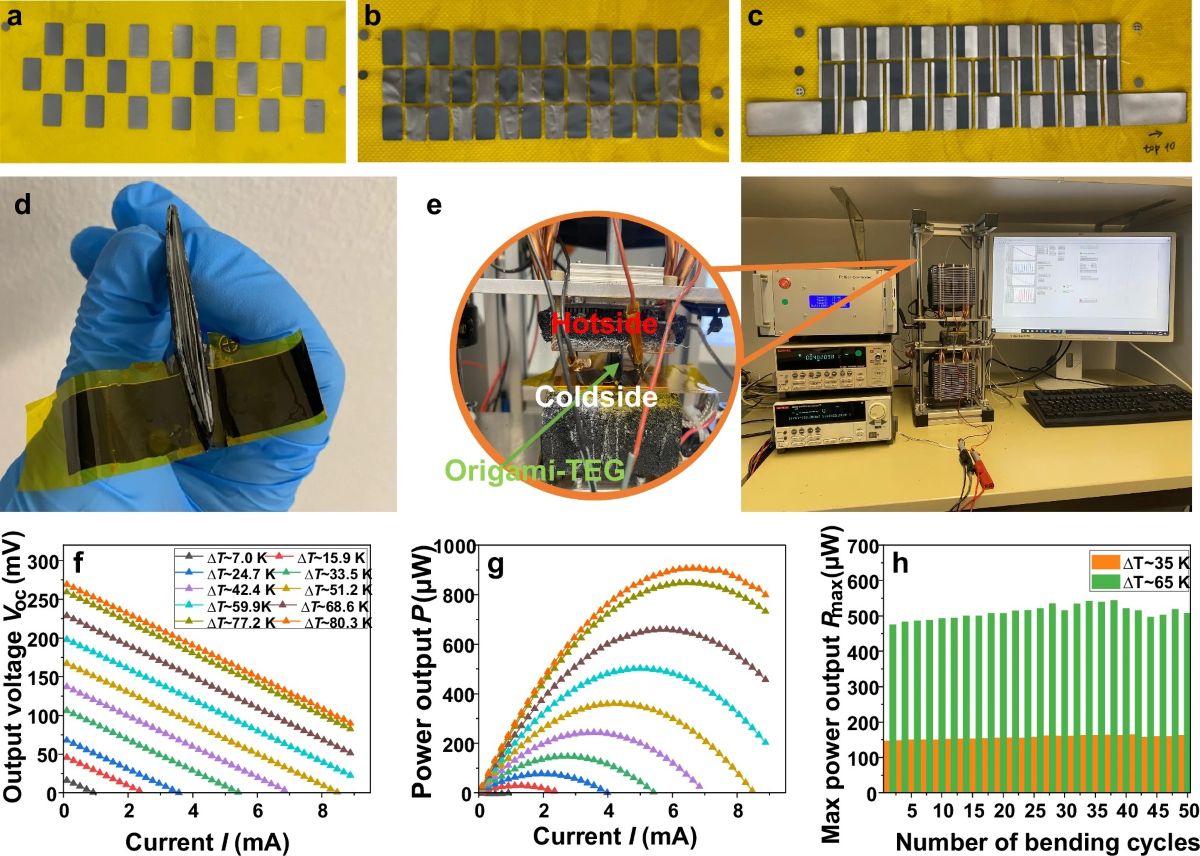

Printed Origami Thermoelectric Generator Achieves Record Power Density

A study published in Nature Communications reports a fully printed origami thermoelectric generator (TEG) with record performance. The study involves Cluster Doctoral Researchers Zirui Wang and Muhammad Irfan Khan, Principal Investigators Yolita M. Eggeler and Uli Lemmer, and Cluster Alumnus Dr. Md Mofasser Mallick. The team developed a flexible, printable thermoelectric material and combined it with an origami-inspired device design to efficiently convert low-grade waste heat into electrical power. The fully printed device achieves a record-high power density, delivering about twice the performance of previously reported printed origami TEGs. The results highlight the potential of printed TEGs as practical, maintenance-free power sources for battery-free IoT devices, wearables, and industrial monitoring systems.

© Luo et al., Nature Communications 17, 1259 (2026), CC BY 4.0.

Second Funding Period Begins

The second funding period of the Cluster of Excellence began on January 1, marking an important new phase for our research activities. To reflect this transition, we have introduced a new research structure that defines our current Research Areas, Sub-Areas, and Projects. The updated website now presents this structure in a clear and accessible way. It also provides an overview of the 42 principal investigators and the broad range of disciplines represented within the Cluster. Our research on scalable digital 3D additive manufacturing is organized into four Research Areas: Molecules & Inks, Technologies, Applications, and Digital Blueprints. These Research Areas form the scientific framework of the Cluster. Interdisciplinary collaboration across these areas is a key element of our work, strengthened through five Lighthouse Projects. We invite visitors to explore the website to learn more about our initiatives and future directions.

Announcing the New Class of Fellows at the Marsilius Kolleg

Heidelberg University introduced the new class of fellows for the 2025/2026 academic year at the Marsilius Kolleg. Among the selected researchers is Cluster Principal Investigator Prof. Dr. Christine Selhuber-Unkel, who will contribute her expertise to the program’s interdisciplinary approach. Directed by Prof. Dr. Friederike Nüssel and Cluster Principal Investigator Prof. Dr. Michael Boutros, the Marsilius Kolleg serves as Heidelberg’s Institute for Advanced Study. The institute fosters collaboration between the natural, life, and engineering sciences, as well as the humanities, cultural studies, and social sciences. During the fellowship year, the new class will explore questions such as how humans acquire and apply knowledge and how these processes can be modeled in AI language models. Another project will focus on interdisciplinary collaboration in researching traditional crops that could support sustainable food systems.

© Tobias Schwerdt

Registration is open for the 3DMM2O Conference 2026

The 3DMM2O Conference 2026 is now open for registration. The event will take place at Schöntal Monastery in Germany from March 23–26. The annual conference is dedicated to exploring the many facets of 3D additive manufacturing. It will highlight advances in the theory, computation, and design of next-generation 3D materials. Researchers and industry professionals are invited to exchange ideas and explore the emerging technologies that are shaping the future of the field. Alongside the scientific program, the conference will feature the traditional Pister Session, as well as a robust social program that fosters community and collaboration. Registration is open until the end of January, and early-bird rates are available until December 22. This year’s program is chaired by Carsten Rockstuhl and Wolfgang Wenzel from the Karlsruhe Institute of Technology (KIT) and Ulrich Schwarz from Heidelberg University.